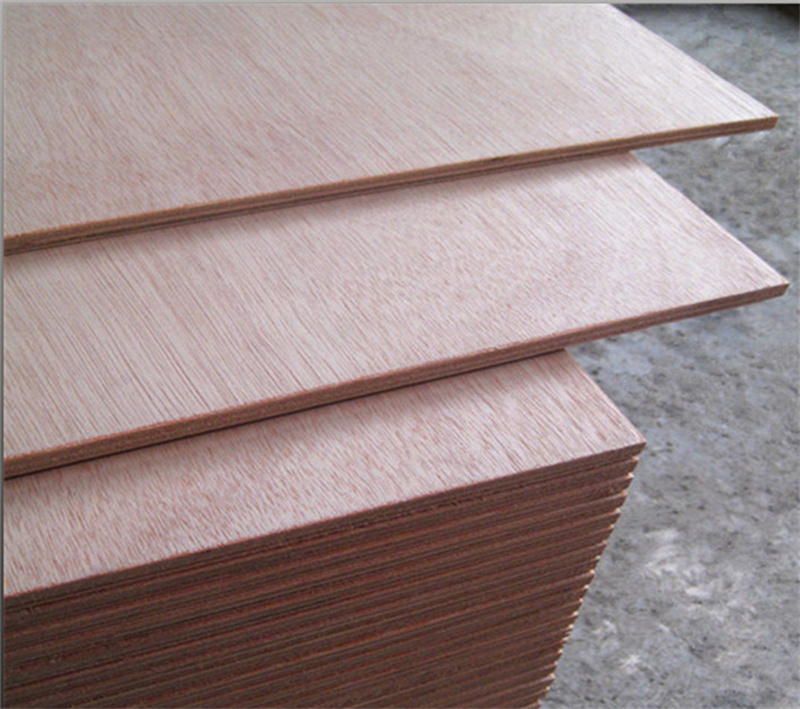

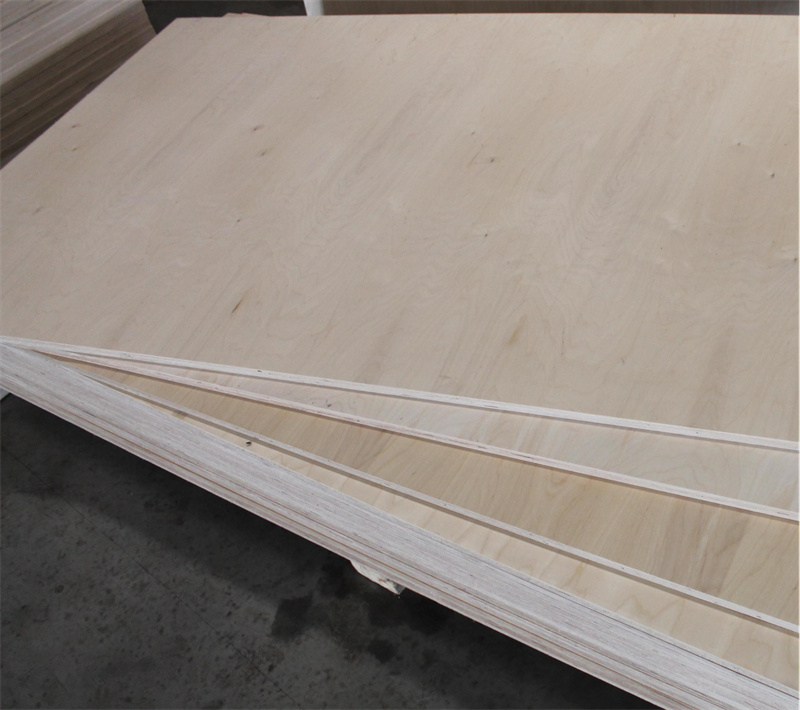

Many woodworking projects have a list of materials used for plywood. Everything from buildings to kitchen cabinets to airplanes benefits from using plywood in the overall design. Plywood is made of large sheets or veneers, which are stacked on top of each other, with each layer rotated 90 degrees in the direction of the wood grain. These layers are bonded together with adhesive and glue to form a large and sturdy panel. Plywood provides a larger coverage area than using a few wooden boards. There are many types of plywood, even heat-resistant and waterproof, further promoting their use in various environments. Nowadays, choosing the right product can be tricky. You must determine the variety, size, and thickness that can complete this task. However, when you visit the plywood section of the local hardware store, the most puzzling question you may ask is, which of these dozens of choices is suitable for my project?

All of this boils down to the scoring system. Not all boards are equal. That is to say, nature does not replicate trees in precise shapes every time. The existence of wood grades is due to the varying quality of wood in nature. Factors such as soil quality, average rainfall, and even local ecosystems can affect the way trees grow. The result is different wood grain, nodule size, nodule frequency, etc. Ultimately, the appearance and performance of a piece of wood vary depending on the tree. At first glance, this seems very simple. There are good and bad, right? Incomplete. For specific projects, even the lowest level may have the highest value. On the contrary, it is best to answer this question by examining the content provided by each level and which level is most cost-effective for the application.

Plywood grading system

Here are six levels of plywood and how each level provides value for woodworking projects.

Plywood is divided into A grade, B grade, C grade, D grade, CDX grade, or BCX grade. Generally speaking, the quality of circuit boards ranges from A best to D worst. In addition, plywood may sometimes come with dual grades, such as AB or BB. In these cases, each level represents one of the sides of the panel. This is a regularly produced product, as many projects only expose one side of the board. Therefore, instead of using high-quality single boards to make a whole board, it is more economical to make all boards except for the surface into lower grade products. In the case of CDX and BCX, they use multiple veneer qualities and special adhesives. The X in these acronym is often mistaken for the exterior grade, but it does mean that a special moisture resistant adhesive is used on the panel structure.

A-grade plywood

The first and highest quality level of plywood is Grade A. This is about selection for board quality. A-grade plywood is smooth and polished, and the entire board has a fine grain structure. The entire polished surface has no holes or gaps, making this grade very suitable for painting. Painted indoor furniture or cabinets are best made of this grade.

B-grade plywood

The next level is Level B,This level truly represents the best wood products in nature. Before any modifications or repairs are made in the factory, many boards often approach B-level. This is because B-level allows for more natural textures, larger unrepaired nodules, and sporadic gaps. Allow closed knots with a diameter of up to 1 inch. If you can smooth out a few knots on the entire board, these boards are still very suitable for painting. This level also allows for very small cracks and discoloration of the board. Many applications use B-grade plywood, including cabinets, outdoor furniture, and furniture. The natural and original appearance of this grade of plywood endows each project with sufficient strength and personality.

C-grade plywood

The next level is the C-level board. Class C, much like Class B, allows for holes ,pores,and knots. Allow diameter up to ½ Inches of closed nodules,and knot holes up to 1 inch in diameter,On these boards, there is much less regulation for splitting. The edges and planes may not be as smooth as B-level. Appearance items may be affected by the looser regulations for C-grade plywood. Applications include structural framing and sheathing.

D-grade plywood

The final main level is level D. The appearance of D-grade wood is very rustic, with a diameter of up to ½ 2 Inches of nodes and pores, major divisions, and severe discoloration. The grain structure will also tend to become loose. Although not the cleanest or easiest to paint, this grade of plywood is not useless. Level D still requires the board to be able to withstand stress and loads for safe use in woodworking projects or large buildings. Truly unnecessary wood is not even suitable for any grade, so you can be confident that even the lowest grade of wood must meet performance requirements. Many structural projects use this level because the wood will be covered no matter what. Strength will provide a durable structure at a discounted price.

Grade BCX plywood

BCX plywood is also common in the plywood section. This level uses a C-level layer and a single B-level layer on one surface. The adhesive used is also moisture-resistant. This specific product is typically used for outdoor applications that still require appearance, including coating or painting. This type of plywood is used for projects such as barn wall panels, agricultural vehicle panels, and privacy fences.

Now that you understand the different types of plywood, you can confidently choose the right product for your job. Whether you need excellent natural finishes, new paint coatings, or just durability, you will know which grade is most suitable for you.

Grade CDX plywood

CDX plywood is a common example of double grade boards. As the name suggests, one side is made of C-grade veneer and the other side is made of D-grade veneer. Usually, the remaining inner layer is made of D-grade veneer to make it more affordable. Moisture resistant phenolic adhesives are also used to further improve performance in humid or humid climates. This grade is the best choice that requires a large amount of plywood, and most of it will be covered up no matter what. CDX plywood is commonly used for exterior walls and sheaths. The C-grade surface provides a smoother surface that contractors can use when installing other parts of the structure, including weather resistant layers and wall panels

Post time: Jun-07-2023