What is medium density fiberboard

Medium density board, also known as MDF board, is actually a board made from wood fibers or other plant fibers, commonly pine, poplar, and hard miscellaneous wood. It is prepared from fibers (rotary cut, steamed), dried, applied with adhesive, laid, heated and pressurized, post-treated, sanded, and pressed. This type of board has a wide range of uses and balanced elastic modulus, and is widely used in fields such as automobiles, food packaging, electrical appliances, shoe heels, PCB electronic circuit board pads, handicrafts, furniture and home furnishings.

There are two commonly used specifications: 1220 * 2440mm and 1525 * 2440mm. The thickness includes: 3mm, 5mm, 9mm, 12mm, 15mm, 16mm, 18mm, 20mm, 25mm,30mm

How many MDFs do we commonly use?

1) PlainMDF: Plain MDF is produced without any decoration and can be pasted with various colors of plain surface.

2. Flame retardant MDF: Flame retardant MDF refers to the addition of flame retardants and other additives during the production of density board to enhance the fire retardant performance of the board. The color is usually red for easy differentiation.

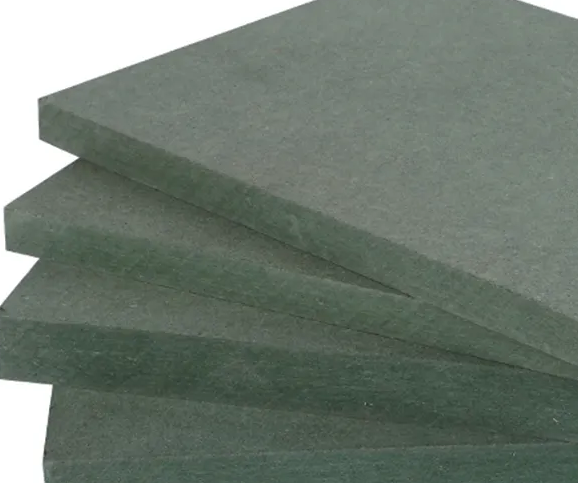

3. Moisture-proof MDF: Fireproof board is made by adding moisture-proof agents and other chemical principles during the production of density board to make the board have moisture-proof and waterproof properties. The color is usually green for easy differentiation;

4. Melamine MDF: There is often a type of decorative board on the market, which uses medium density board as the core material and is coated with melamine paper on the surface. The advantage of this type of board is that it is not easily deformed due to moisture, and it is anti-corrosion and wear-resistant. It is commonly used as a door panel for cabinets.

Advantages of MDF:

1. MDF boards are easy to finish. Various PVC, wood veneer, technological wood veneer, coatings, and paints can be uniformly adhered to the density board substrate;

2. The surface of the medium density board is smooth and flat, the internal structure is uniform, the material is fine, the performance is stable, the structural stability is good, the thickness can reach 1-25mm, the surface material color is uniform, and the finish is beautiful.

3. The physical properties of medium density board have resistance to impact and bending, and it is not easy to crack. It is soft, impact resistant, and easy to process. It can be made into any shape according to the customer’s requirements, with good plasticity. Commonly used on wooden floors, door panels, and furniture.

4.) Medium density boards can also prevent noise and absorb sound, so they are often seen in many building decoration projects.

Disadvantages of MDF:

1. The gripping force of medium density board is poor, and due to the extremely fragmented fibers with high density, the gripping force of medium density board is much worse than that of solid wood board and particle board.

2.) The waterproof performance is poorer than that of solid wood, which is prone to water absorption, expansion, deformation, or delamination of the veneer;

How to choose MDF boards?

1. Cleanliness

When purchasing medium density boards, we can first take a look at the surface cleanliness. If there are no obvious particles on the surface, then it is a high-quality density board.

2. Smoothness

If the surface of the medium density board feels uneven when touching it with your hand, it indicates that it has not been processed properly.

3. Flatness

The surface smoothness of density boards is also very important. If they appear uneven, it is a low-quality medium density board with incomplete materials or coating processes.

4. Hardness

Medium density board is made from wood fibers. If the board is too hard, the quality of this density board is questionable.

5. Water absorption rate

The water absorption expansion rate is very important for medium density boards. Medium density boards with poor water resistance will experience significant expansion and size changes in damp environments, which will also affect their use later on.

Post time: Aug-28-2023